Induction hardening versus case hardening – a comparison

€4.90

In stock

article number

00541_2015_01_07

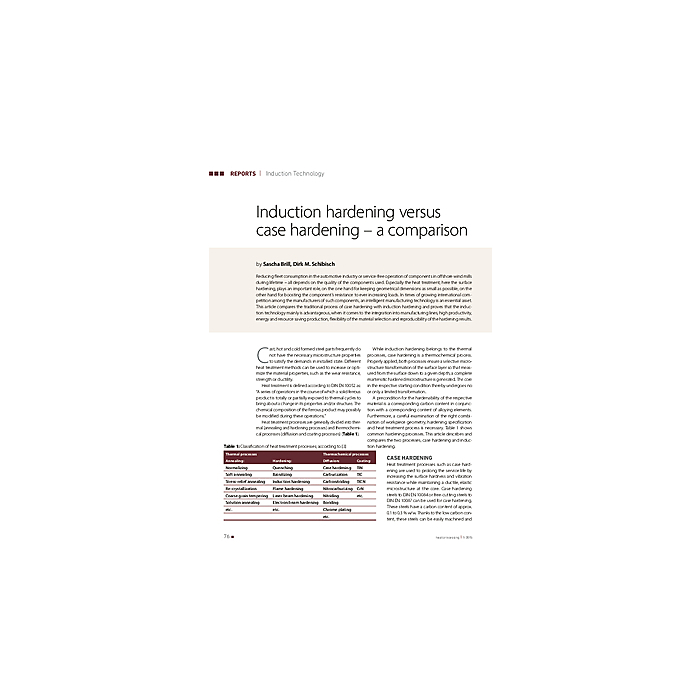

Reducing fleet consumption in the automotive industry or service-free operation of components in offshore wind mills during lifetime – all depends on the quality of the components used. Especially the heat treatment, here the surface hardening, plays an important role, on the one hand for keeping geometrical dimensions as small as possible, on the other hand for boosting the component’s resistance to ever increasing loads. In times of growing international competition among the manufacturers of such components, an intelligent manufacturing technology is an essential asset. This article compares the traditional process of case hardening with induction hardening and proves that the induction technology mainly is advantageous, when it comes to the integration into manufacturing lines, high productivity, energy and resource saving production, flexibility of the material selection and reproducibility of the hardening results.

| Authors | Sascha Brill / Dirk M. Schibisch |

|---|---|

| Publishing Date | 1 Jan 2015 |

| Format | |

| Zeitschrift | heat processing - Issue 01 2015 |

| Publisher | Vulkan-Verlag GmbH |

| Language | English |

| Pages | 8 |

| Title | Induction hardening versus case hardening – a comparison |

| Description | Reducing fleet consumption in the automotive industry or service-free operation of components in offshore wind mills during lifetime – all depends on the quality of the components used. Especially the heat treatment, here the surface hardening, plays an important role, on the one hand for keeping geometrical dimensions as small as possible, on the other hand for boosting the component’s resistance to ever increasing loads. In times of growing international competition among the manufacturers of such components, an intelligent manufacturing technology is an essential asset. This article compares the traditional process of case hardening with induction hardening and proves that the induction technology mainly is advantageous, when it comes to the integration into manufacturing lines, high productivity, energy and resource saving production, flexibility of the material selection and reproducibility of the hardening results. |

Write Your Own Review