Furnace model predictive control forecasts transitions to enhance strip quality and productivity

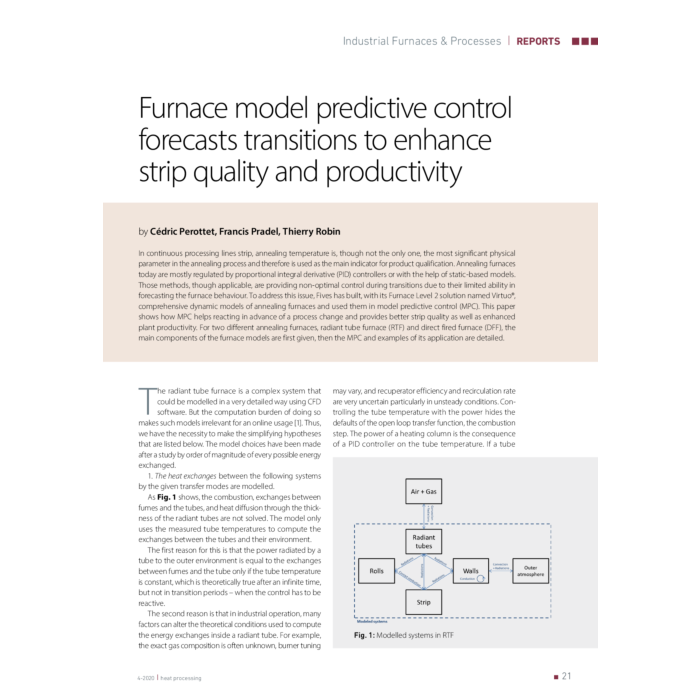

In continuous processing lines strip, annealing temperature is, though not the only one, the most significant physical parameter in the annealing process and therefore is used as the main indicator for product qualification. Annealing furnaces today are mostly regulated by proportional integral derivative (PID) controllers or with the help of static-based models. Those methods, though applicable, are providing non-optimal control during transitions due to their limited ability in forecasting the furnace behaviour. To address this issue, Fives has built, with its Furnace Level 2 solution named Virtuo®, comprehensive dynamic models of annealing furnaces and used them in model predictive control (MPC). This paper shows how MPC helps reacting in advance of a process change and provides better strip quality as well as enhanced plant productivity. For two different annealing furnaces, radiant tube furnace (RTF) and direct fired furnace (DFF), the main components of the furnace models are first given, then the MPC and examples of its application are detailed.

| Authors | Cédric Perottet, Francis Pradel, Thierry Robin |

|---|---|

| Publishing Date | 23 Nov 2020 |

| Format | |

| Publisher | Vulkan-Verlag GmbH |

| Language | English |

| Title | Furnace model predictive control forecasts transitions to enhance strip quality and productivity |

| Description | In continuous processing lines strip, annealing temperature is, though not the only one, the most significant physical parameter in the annealing process and therefore is used as the main indicator for product qualification. Annealing furnaces today are mostly regulated by proportional integral derivative (PID) controllers or with the help of static-based models. Those methods, though applicable, are providing non-optimal control during transitions due to their limited ability in forecasting the furnace behaviour. To address this issue, Fives has built, with its Furnace Level 2 solution named Virtuo®, comprehensive dynamic models of annealing furnaces and used them in model predictive control (MPC). This paper shows how MPC helps reacting in advance of a process change and provides better strip quality as well as enhanced plant productivity. For two different annealing furnaces, radiant tube furnace (RTF) and direct fired furnace (DFF), the main components of the furnace models are first given, then the MPC and examples of its application are detailed. |